Services

What we offer

The installation and maintenance of the refractory lining is the basis from which REVESTIMIENTOS REFRACTARIOS, S.A. has boosted its development. We have a highly qualified team with extensive experience in the installation and maintenance of refractory linings in all types of industrial facilities. Our signs of identity are fast response and the adaptability to the needs of our customers.

Instalation of refractory

With the goal to provide “turnkey” Integral Services, REVESTIMIENTOS REFRACTARIOS, S.A. offers to its clients the most complete range of activities that involves the replacement of a refractory lining, optimizing the intervention time and facilitating coordination tasks:

- Assembly of scaffolding: supply and installation of Layher material by qualified personnel.

- Demolition

- Cleaning of plates by sandblasting

- Application of anticorrosion paint

- Welding of anchors: by manual arc and stud welding

- Gunite

- Vibrocasting

- Mini shot-creting

- Pumping

- Molded

- Pneumatic compacting

- Installation of bricks and insulation panels

- Installation of Ceramic Fiber

Hexmesh & anchors

During the last years of service, Revestimientos Refractarios, S.A. has been developing and expanding nationally and internationally is in the welding of metallic elements for, especially, FCC units.

It is in these units where we have the ability to install and weld hexmesh, adjusting to the repair area, having the capacity to work with another elements such as special tabs, studs, corner tabs, U-tabs, Radius Tabs, Ending Bars.

For the welding result to be ideal, we have a team specially prepared with the means and experience to remove the existing hexmesh and perfectly grind the surfaces where the hexmetal will be installed.

Not only we provide responsiveness and quality in these specific works, but we are also able to offer clients different solutions for each case, always complying with the applicable standards that are well known to our supervisors and site managers.

Similarly, in monolithic gunned or vibrated refractory installations, we weld the necessary anchors to carry out this work. Here after demolition, we evaluate with the client and / or inspector the condition of the existing anchors and decide whether to cut and weld anchors next to the existing ones or to keep them if their condition is optimal.

In accordance with market demands and in order to work in any plant in the world, R.R. has approved welding procedures for different materials under European Norms and ASME Section IX.

Supplies

During our years of service we have made numerous supplies of refractory materials for the lining of equipment, both nationally and internationally. In the national market this material has been issued to a multitude of companies, among which it is worth highlighting: REPSOL, CEPSA, SABIC.

We have made supplies abroad, normally through engineering companies, taking care of maritime packaging and all the necessary documentation for export in Spain and import in the destination country. We have also performed triangular operations. Our main clients in these operations have been INITEC, TÉCNICAS REUNIDAS, FOSTER WHEELER and JOHN DEERE. The countries of destination of our material supplies have been, among others: Greece, China, Mexico, Iran, Egypt, Turkey, Morocco, Cuba, Chile.

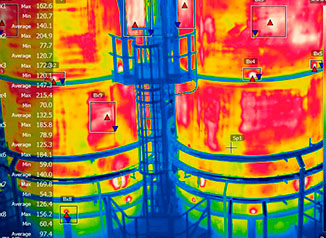

Inspections & technical assistance

REVESTIMIENTOS REFRACTARIOS, S.A. offers its customers Technical Assistance for their projects. This work is carried out completely in our Technical Office, based on our calculation programs and our extensive experience in installations and materials. Our studies and plans include:

- Thermal studies.

- Energy efficiency.

- Design of formwork and anchoring systems.

- Coating drying programs.

- On-site inspection and / or supervision services.

R.R. employs six API 936 inspectors with proven extensive experience on the field. Part of this team is dedicated, when required, to act as an inspection body directly contracted by the end user (refinery ownership) for all refractory activities on the FCCU.

Have questions? Contact us for details